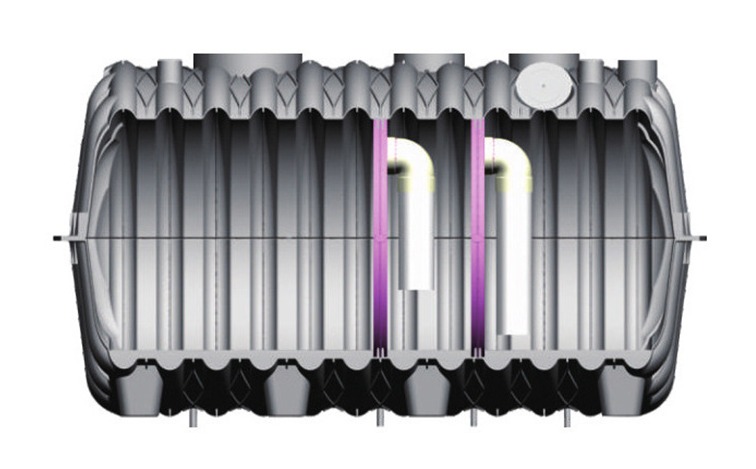

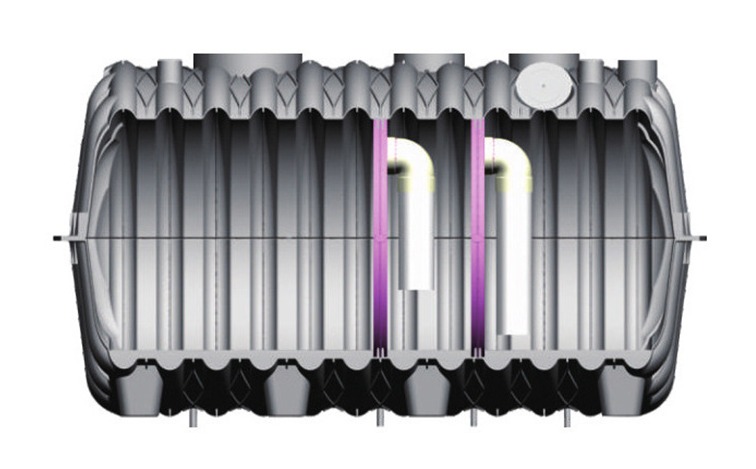

In modern commercial kitchens and industrial facilities, plastic grease traps and plastic oil-water separators are essential for managing fats, oils, and other contaminants before wastewater enters municipal systems. While these devices are crucial for operational efficiency, they are also subject to regulations that ensure environmental safety.

At Weicai, we design and manufacture plastic grease traps and plastic oil-water separators that not only meet performance needs but also align with current regulatory standards. This article will explore the key regulations surrounding these devices and provide practical guidance on maintaining compliance.

Environmental Regulations and Standards

Regulatory bodies at the federal, state, and local levels often define how grease traps and oil-water separators must be installed and maintained. For instance:

EPA Guidelines: The Environmental Protection Agency sets standards for devices like plastic oil-water separators, specifying the acceptable levels of oil and grease in wastewater discharge. These guidelines are designed to prevent water pollution and minimize the risk of blockages in sewer systems.

Local Plumbing Codes: Many municipalities have specific requirements for the installation, sizing, and maintenance of plastic grease traps. These codes may include mandatory cleaning schedules, inspections, or documentation to verify compliance.

Now that we understand the general regulatory framework, let’s look at the practical implications for businesses.

Installation Compliance

Correct installation is a critical factor in meeting regulatory requirements. Improperly installed plastic oil-water separators or plastic grease traps may fail to separate contaminants effectively, cause to fines or environmental hazards. Here are key considerations:

Placement: Install devices in accessible locations to facilitate inspection and maintenance.

Sizing: Choose the correct size based on water flow rates and grease or oil production. Oversized or undersized units can fail regulatory inspections.

Connection: Ensure all inlet and outlet pipes are properly sealed and routed according to local codes.

Inspection Access: Include manholes or removable lids to allow for easy inspection without dismantling the unit.

At Weicai, our products are designed with these compliance needs in mind, featuring durable lids, clear inlet/outlet points, and easy maintenance access.

Maintenance and Record-Keeping

Regulations often emphasize maintenance and record-keeping as much as installation. Businesses are usually required to:

Schedule Regular Cleaning: Establish routine cleaning intervals depending on grease or oil output.

Document Maintenance Activities: Keep logs of cleaning dates, personnel, and quantities of waste removed.

Monitor Efficiency: Periodically test plastic oil-water separators to ensure they are effectively separating oil and water.

Maintaining detailed records not only ensures compliance but can also help identify performance issues before they escalate.

Inspection and Enforcement

Authorities may conduct periodic inspections to verify that plastic grease traps and plastic oil-water separators meet standards. Non-compliance can result in warnings, fines, or even temporary shutdowns. Common inspection points include:

Evidence of regular cleaning and maintenance

Proper installation and access for monitoring

Efficient operation with no excess oil or grease entering the sewer

Understanding these enforcement measures can help businesses proactively maintain compliance.

Regulations surrounding plastic grease traps and plastic oil-water separators are designed to protect the environment and prevent system failures. Understanding these rules, installing devices correctly, maintaining proper records, and performing regular inspections are essential for compliance. At Weicai, our products are engineered with both efficiency and regulatory adherence in mind, helping businesses achieve operational success while meeting environmental responsibilities.

English

English русский

русский Español

Español عربى

عربى