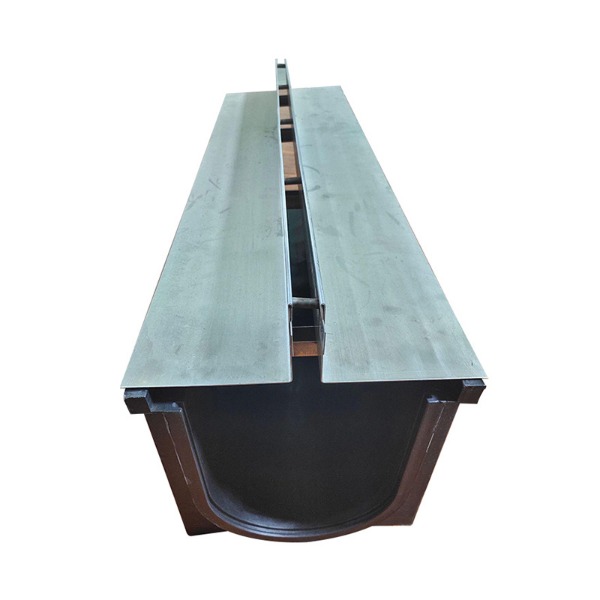

Balcony Roof Rainwater Separator

Cat: Separated Oil Well

The balcony roof rainwater and sewage separator is a crucial component in urban water management systems, designed to effectively separate rainwa...

See DetailsA contemporary plastic drainage system has emerged as the preferred option for improving infrastructure resilience and urban water control in recent months. As cities grow denser and climate events become more unpredictable, municipalities and engineers are searching for ways to better manage stormwater. The implementation of an advanced Plastic Drain Channel design is transforming how stormwater runoff is handled in public spaces, roadways, and construction zones.

Understanding Urban Drainage Challenges

Urban areas face unique drainage issues caused by:

High levels of impervious surfaces like asphalt, concrete, and rooftops, which prevent natural water absorption.

Limited green infrastructure, reducing the ability of soil and vegetation to buffer rainwater.

Aging infrastructure, much of which was built decades ago and cannot accommodate today's rainfall intensity.

In such conditions, outdated systems may fail to capture water efficiently, resulting to street flooding, traffic disruption, and even property damage. This is where the new generation of plastic-based drainage infrastructure becomes invaluable.

The Plastic Drainage System Advantage

1. Lightweight Yet Durable

Unlike traditional concrete drainage solutions that require heavy lifting equipment, the Plastic Drain Channel system is designed to be lightweight, making it easier and faster to install. Despite its light weight, the system can withstand significant load-bearing demands—making it suitable for both pedestrian areas and light vehicle traffic zones.

2. Corrosion and Chemical Resistance

Plastic materials like HDPE and polypropylene are naturally resistant to corrosion, rust, and many chemicals found in urban runoff. This extends the system’s life cycle and ensures stable performance even under harsh weather or industrial pollution exposure.

3. Modular and Scalable Design

Each segment of the drainage channel is modular, allowing for customized layouts that adapt to complex terrains. Whether a project involves a narrow alley, large commercial parking lot, or a landscaped park, these channels can be tailored accordingly without needing redesign from scratch.

Key Benefits for Urban Areas

Faster Rainwater Removal

Smooth internal channel walls minimize friction, helping rainwater flow more efficiently through the system.

Low Maintenance Requirements

Anti-silt and anti-debris design elements reduce the risk of clogging, which can lower maintenance frequency and operational costs.

Simplified Transport and Handling

Lightweight plastic components reduce labor intensity and eliminate the need for cranes or forklifts in smaller installation projects.

Real-World Use Cases

1. Roadway Projects

Several municipalities have installed the system along highway shoulders and busy intersections. The result: faster runoff and fewer puddles after storms, enhancing both safety and road longevity.

2. Industrial Parks and Warehouses

In zones where heavy-duty machinery operates, reinforced plastic channels with steel grates are used to manage chemical-laden runoff while maintaining structural integrity.

3. Residential Community Parks

In green spaces, these drainage channels blend well with the landscape and can be integrated under grass, walkways, or gravel paths, preserving the visual appeal of the area.

4. Flood-Prone Intersections

Pilot tests in southern cities showed that plastic channels helped reduce standing water time by over 40% during seasonal rains.

Technical Considerations

When choosing or installing a plastic drainage system, several engineering parameters should be reviewed:

Load Class: Ensure compatibility with expected traffic—pedestrian, light vehicle, or truck.

Flow Rate Calculations: Design based on rainfall intensity and surface area to ensure adequate channel sizing.

Outlet Positioning: Proper slope and outlet design help avoid water stagnation or backflow.

Cover Options: Select from various grating materials—plastic, galvanized steel, or ductile iron—depending on the application.

With its durability, ease of installation, and environmental compatibility, this system is well-positioned to meet current and future urban water challenges—one project at a time.

It would be great to hear from you!