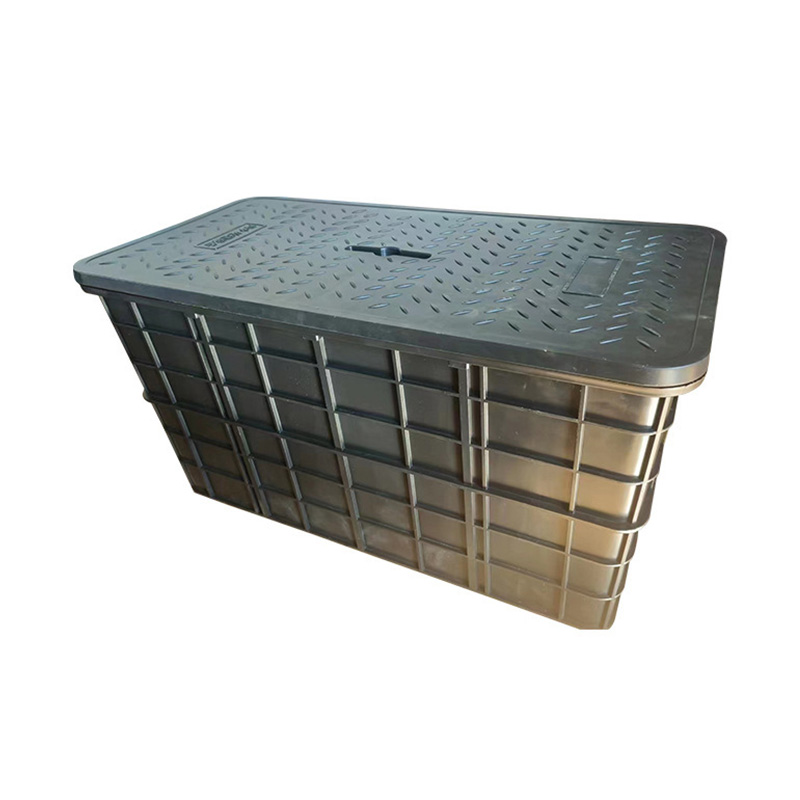

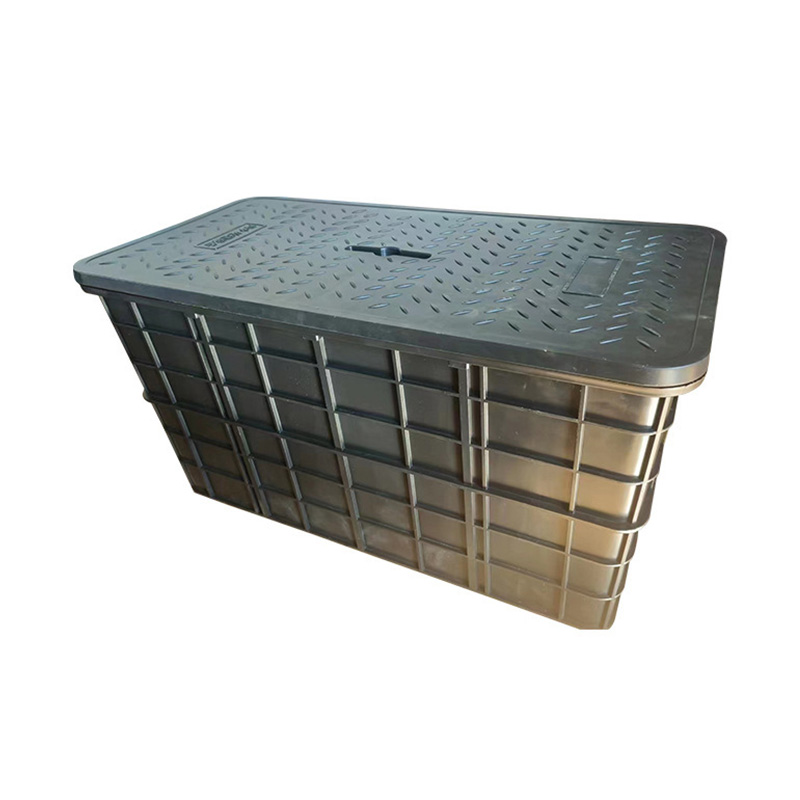

Managing oil-contaminated water is a daily responsibility in many industrial and automotive environments. From workshop floors to factory production lines, proper separation of oil and water not only supports cleaner operations but also helps businesses meet environmental regulations. Among the available solutions, the plastic oil water separator has become a widely used tool because of its durability, lightweight design, and reliable performance. In this article, we’ll explore the common applications for an oil water separator in both industrial and automotive settings and why it continues to be a preferred choice.

Industrial facilities frequently produce wastewater containing oil from equipment, machinery, and processing systems. A plastic oil water separator plays a key role in ensuring these operations manage their waste responsibly.

In production environments where cutting fluids, lubricants, and hydraulic oils are used, wastewater often carries oil residues. Installing a plastic oil-water separator in these facilities helps separate oil before the water is either reused or safely discharged.

During machining, grinding, and polishing processes, metalworking shops generate oil-laden wastewater. An oil-water separator assists in managing this waste by efficiently removing oils and reducing the environmental impact of disposal.

Food industries sometimes deal with oily wastewater, particularly in frying and preparation areas. A plastic oil water separator is used here to manage fats, oils, and greases, preventing them from entering water systems and clogging drains.

Chemical plants use various oils in processing and equipment maintenance. A plastic oil water separator can safely manage oily water generated during cleaning operations, preventing chemical contamination of wastewater systems.

The automotive sector consistently produces oily water from vehicle maintenance, cleaning, and repair operations. The oil water separator provides a practical, cost-effective solution in these settings.

In repair garages and service centers, water mixed with engine oil, brake fluid, and grease frequently runs off from floors and equipment. A plastic oil water separator captures and separates these oils, ensuring wastewater systems remain clear and compliant with local regulations.

Car washes generate large volumes of wastewater containing detergents, dirt, and oil residues. A plastic oil water separator installed within the drainage system prevents oils from entering the sewage system, protecting both plumbing and the surrounding environment.

Spillage and surface runoff at gas stations can result in oil-contaminated water. A plastic oil water separator manages these liquids before they reach drainage systems, ensuring safer and cleaner site operations.

Businesses operating large fleets of trucks, buses, or service vehicles often deal with oil leaks and wash water runoff. Installing a plastic oil water separator in these facilities helps capture hydrocarbons before they enter stormwater systems.

Across both industries, the plastic oil water separator is favored for several practical reasons:

Corrosion Resistance: Plastic components perform well in environments with exposure to chemicals, moisture, and fluctuating temperatures.

Lightweight Construction: Easier to install, relocate, and maintain compared to heavier metal models.

Durability: Withstands regular use in demanding industrial and automotive conditions.

Cost-Effective Operation: Offers reliable separation with lower maintenance requirements over time.

The plastic oil water separator serves a vital function in both industrial and automotive fields by improving wastewater management and protecting local water systems. Whether installed in a manufacturing plant, car wash, or fueling station, this simple yet effective device helps reduce environmental risks while supporting smooth daily operations. As industries continue to focus on sustainability and operational efficiency, the plastic oil water separator remains a valuable, practical solution for managing oil-contaminated water in a wide range of commercial settings.

English

English русский

русский Español

Español عربى

عربى